Next-Gen Caribbean Airports: Harnessing GFRP for Sustainable, Resilient Airfield Infrastructure

- visiondev2

- Jul 23, 2025

- 4 min read

As Caribbean airports face increased passenger and freight demands alongside escalating climate resilience challenges, incorporating cutting-edge materials is essential. Glass Fiber Reinforced Polymer (GFRP) rebar is emerging as a transformative solution—offering steel-like strength without steel’s vulnerabilities, along with unique benefits critical to tropical airport environments.

From ICAO-compliant frangible support systems to electromagnetic-safe infrastructure near radar towers, the integration of GFRP is not just innovative it’s imperative

Why GFRP? Superior Performance in Coastal Aviation Infrastructure

Glass Fiber Reinforced Polymer is a composite material formed by embedding high-strength glass fibers in a polymer matrix. It is engineered for structural reinforcement without the weight, corrosion, or conductivity of steel. For the aviation sector, particularly across coastal and island-based airfields like those in the Caribbean, this translates into unmatched longevity and performance in salt-laden environments.

Steel corrosion in coastal areas is a multimillion-dollar maintenance problem, especially where salt spray, humidity, and heat accelerate deterioration. GFRP eliminates this vulnerability. It is:

Non-corrosive, eliminating rust-related failures

Electromagnetically transparent, reducing signal distortion around sensitive avionics

Lightweight, cutting freight and placement costs by up to 70%

Stronger than steel by weight, with tensile strength over 1,000 MPa

Non-conductive, enhancing safety near electrical systems and lightning-prone zones

Electromagnetic Safety: Why Non-Metallic Matters in Aviation

Traditional rebar and fencing systems made of steel can interfere with airport radio frequency (RF) and radar operations. In critical zones—such as near control towers, VOR/DME stations, and Instrument Landing Systems (ILS) even slight electromagnetic disturbances can affect flight safety.

GFRP’s dielectric nature means it does not absorb, block, or distort electromagnetic signals. Its use in structures surrounding radar domes, perimeter fencing, and even embedded in pavements near high-sensitivity zones makes it ideal for compliance with FAA and ICAO safety guidelines.

GFRP also plays a critical role in maintaining safety around navigational equipment, ensuring full signal fidelity across systems like Doppler VOR stations and ILS glide slope antennas.

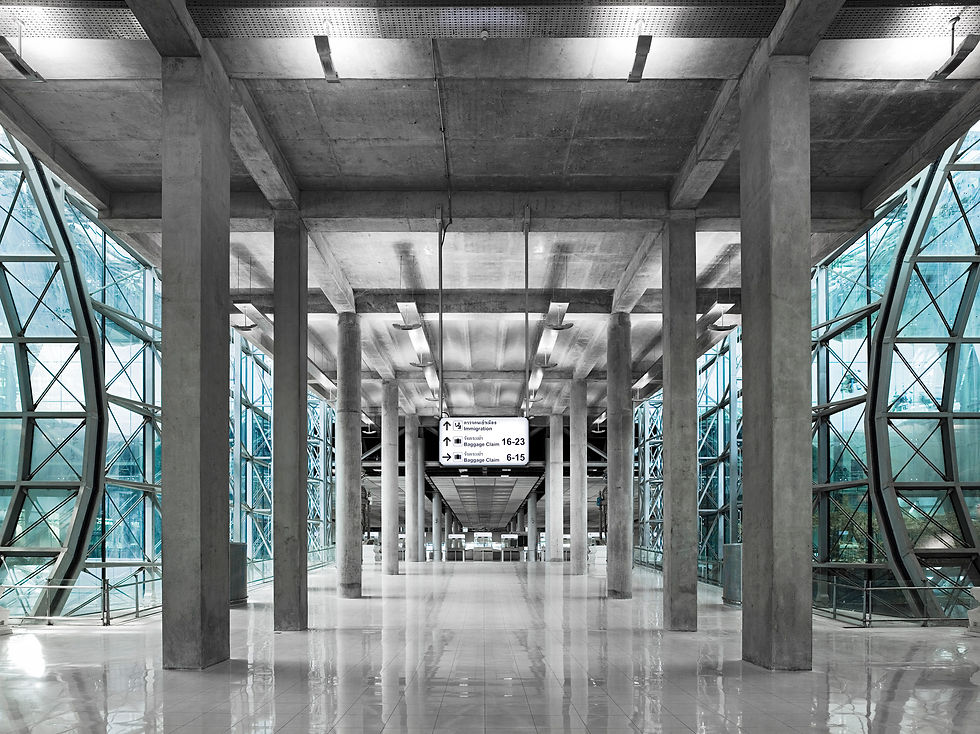

Suvarnabhumi Airport: A Benchmark for GFRP Deployment

One of the most compelling case studies in GFRP use is Bangkok’s Suvarnabhumi International Airport. As part of its major expansion, the airport deployed Dextra’s GFRP reinforcement in taxiways, runways, and drainage systems. These areas face high axle loads from aircraft like the Airbus A380, extreme monsoon flooding, and tropical temperatures that make steel corrosion an inevitability.

GFRP’s benefits at Suvarnabhumi included:

Zero RF interference near the ATC tower and navigation arrays

Extended lifespan of underground drainage and utility corridors

Corrosion-free performance during peak flood cycles

Faster construction due to lightweight material and pre-bent formwork

Compliance with FAA and ICAO safety specs

This project became a global example of how GFRP could combine durability, speed, and aviation-grade performance in critical airport infrastructure.

Implications for Caribbean Airports: From Antigua to Grand Bahama

Caribbean airports often straddle oceanfronts, coral soils, and wetland estuaries. Steel rebar, fencing, and support systems degrade rapidly under such exposure. Maintenance costs and downtime ripple across tourism, shipping, and emergency response.

Introducing GFRP into airside and landside infrastructure across the region especially via Rebella CCR and Dextra’s systems offers a way to leapfrog into a more resilient, sustainable aviation future.

Rising sea levels

Intensifying hurricanes

Escalating maintenance costs due to climate-induced degradation

Key Applications in the Caribbean Context:

Application | Traditional Material | GFRP Advantage |

Runway edge drainage | Corroded steel | Non-corrosive, 100-year lifespan |

Radar zones | Steel rebar causes EMI | GFRP ensures signal clarity |

Security fencing | Rust-prone mesh | ICAO-compliant FibreFENCE GFRP fencing |

Meteorological towers | Steel masts (hazardous) | Frangible GFRP masts (impact-safe) |

Foundation reinforcement | Rusting rebar | Long-lasting composite bars |

Sea wall toe walls | Concrete with rebar | GFRP reinforcement resists saltwater intrusion |

♻️ Sustainability & LEED Certification: A New Frontier for Airfields

Beyond structural and safety considerations, GFRP enhances airport sustainability. Rebella CCR’s system supports LEED v4 and v5 targets, including:

Material Reuse & Durability (MR Credit)

Reduction of Heat Island Effect (SS Credit)

Reduced Embodied Carbon (using GFRP vs steel)

Recyclable content GFRP can be reclaimed or repurposed

Energy savings lighter weight structures reduce machinery fuel loads during construction

GFRP also integrates smoothly with solar carports, modular terminals, and passive drainage systems for stormwater management—crucial in hurricane-prone zones.

Faster Builds. Less Freight. More Resilience.

The Caribbean’s geography makes freight cost, timing, and storage logistics critical. GFRP’s low weight (1/4 that of steel) and ability to be shipped in pre-bent, pre-cut cages allows for:

Reduced freight costs by up to 50%

Easier last-mile transport to remote islands

Faster site prep—no heavy lifting cranes required

Safer installation in high-humidity or waterlogged zones

With ports like Bridgetown, Kingston, and Nassau undergoing modernizations, GFRP is positioned as a smart default material—not just an alternative.

A Modular Future: GFRP in Composite Airfield Kits

Rebella CCR is currently working with manufacturers to offer pre-designed modular composite kits for Caribbean airports. These include:

GFRP-reinforced slabs for helipads

Modular emergency response hangars

Radar perimeter fencing

Lighting mast foundations

Portable ILS support structures

GFRP + flood barrier toe-wall systems for seawalls and aprons

These innovations position Rebella not just as a material supplier—but as a full-stack aviation infrastructure partner.

Why This Matters Now

As global aviation rebounds post-pandemic and climate resilience becomes central to infrastructure funding (including via climate bonds and World Bank assistance), Caribbean nations must rethink airport design. Climate-resilient runways, corrosion-free control zones, and EMI-safe nav systems will be non-negotiable for operational continuity and investor confidence.

GFRP is not a futuristic material—it is already here, proven in Asia, Europe, and the Middle East. The opportunity is to deploy it at scale, smartly, and with regional specificity.

Futureproofing Caribbean Skies

The case for GFRP in aviation isn’t theoretical. It’s practical, tested, and now—regionally available.

Rebella CCR, in collaboration with Dextra Group, provides engineered GFRP reinforcement systems tailored for Caribbean geographies, design codes, and logistical realities. Whether you’re planning an airstrip in St. Vincent or expanding a terminal in the Bahamas, the time to adopt next-gen materials is now.

Contact Us

Engineers, developers, government planners, and consultants can reach out to:

🤝 Consultation slots available via direct booking

🏁 In Closing

Caribbean airports sit on the frontlines of both opportunity and risk. Investing in smart infrastructure like GFRP isn’t just about durability—it’s about creating a smarter, safer, and more sustainable aviation experience for generations to come.

Would you like this version exported as a PDF layout or prepped for LinkedIn or Substack distribution with images and pull quotes?

\

Comments